How To Save Enormous Sums Of Money On Wood, Tools & Other Woodworking Materials

- Written By: The Good Lifestyle

- October 5, 2022

- 9:12 am

You’ll be amazed at how much profit you can make from your woodworking projects when you cut down the cost of production without compromising quality.

Yes, it’s possible… and that’s what you’ll discover today.

These are some areas where you can cut down costs:

- Tools

- Raw materials

- Time and technique

Table of Contents

Save Money On Wood

Wood is your single largest cost in woodworking. And you can save money on wood using these methods, regardless of whether your demand for wood is high or low;

- Find a lumberyard

- Shop online ( this one may sound strange, but it works)

- Plan your purchase, and shop on offers and discounts

- Substitute with high quality board and veneer

- Build relationship with a local vendor

You may not have known that lumber yards and online retailers are willing to fulfill even small orders…

Well, they do. And that’s good news for you. Plus, you can get a lot of help at the lumberyard.

Here you’ll find the wood is already cut and stocked according to grade and size. Also you will find maximum variety as well as the best price.

Online retailers are very helpful too. You can simply ask for the specifications of the wood you’re looking for and they will send it to you. In fact, they also take orders over the phone as well.

And the best part is…

You can inspect the wood when it’s delivered to your doorstep and on the rare occasion something is not what you ordered, you can return it for a free exchange.

Ordering wood online and over the phone may seem strange at first. But once you begin, you’ll discover you can enjoy great discounts with this method of ordering, and it soon becomes a convenient way of doing business.

Saving On Tools

The first method of saving on tools is not to buy what you do not need in the first place. Pretty obvious, right?

Well, you can control this by controlling what you make when you first start your woodworking business.

Now, as you build your woodworking business, you’ll discover power tools are useful because they save time and effort, and increase your productivity.

Although they’re definitely not a prerequisite for starting your woodworking business, you should use them whenever it’s possible.

Alright, there are some neat tricks you can use whenever you are in the market for some power tools. Look for online sales discounts and discount vouchers in woodworking magazines. You can get some really big discounts online.

So what you need to do is join the newsletter of all the major woodworking websites and opt-in to be notified whenever there are upcoming promotions.

Your second best option is to buy refurbished tools. Refurbished tools not second hand tools. We don’t usually recommend second hand tools. We’ll come to that in a moment.

Refurbished tools are pre-owned tools that have been restored to new-like condition by the company selling it. This could be done by the original manufacturer, an online store or local hardware store that deals in refurbished tools.

You can look around to see where you can find them. Many major online stores have a section for ‘refurbished tools’. It won’t be in your face, so you’ll need to find the link to this section.

Talking about second hand tools, we usually do not recommend them. In most cases you don’t know anything about the tool. You can’t see any wear and tear that’s not apparent to the naked eye. And that’s the kind of wear and tear that counts.

Also, there’s usually no guarantee on second hand tools. In contrast, refurbished tools almost always come with a guarantee.

So unless you know the history of the tool, do not purchase second hand. You do not know if the tool has previously been repaired.

And in the event that it’s been fixed before, you can be sure that it’s life has been greatly shortened. Repairing it again will cost you more money and won’t be worth the use you get from it.

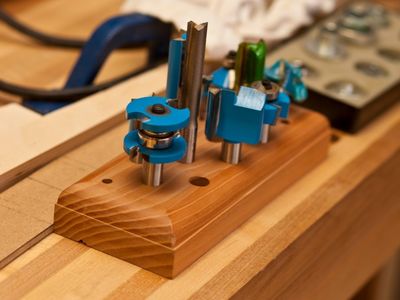

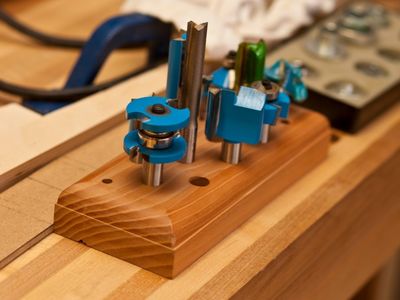

Use Superior Accessories

This is a cost effective technique to make cheaper consumer power tools give industrial grade results, allowing you get more out of your existing woodworking tools.

You can get better, faster and more accurate results by using high quality accessories like carbide router bits.

Another benefit of using superior accessories is…

High grade accessories make your tools last longer because they cut, grind and finish with a greater degree of ease, thereby putting less strain on your machinery.

We highly recommend downloading Wood Profits for hundreds of products you can start making and selling without the need for expensive tools.

Time & Money Saving Techniques

You can make more money, if you can save time when making a woodcraft. And there are definitely ways you can do your project faster.

There are faster ways to do joinery, install drawers etc. Although woodworkers take pride in doing some things the classic way, the additional time spent on a project raises the cost of the project, which the customer is required to pay for ultimately.

So cutting down on your production time benefits both you and the customer.

Once again, we come back to one of our golden mantras to make more money with your woodworking effort. Make easy, simple and high in-demand woodcrafts with Wood Profits.

What Next?

I want to share with you detailed plans for these woodworking crafts and a more comprehensive step by step guide to start earning money with woodworking.

In This Guide You’ll Discover:

- 500+ top selling crafts and furniture plans

- Discover where to buy your tools and materials at discounts

- The “Craft Secret” (If you know it, you could build anything and people would still pay you premium prices…)

- The exact words you should use to sell your products that increase sales…(learn to close the sale without coming off as pushy or desperate)

- And lots more on the next page…

You’ll get the detailed plans and comprehensive guide that’ll show you how to create top-selling woodwork crafts and how to profitably sell them to start earning money from home.